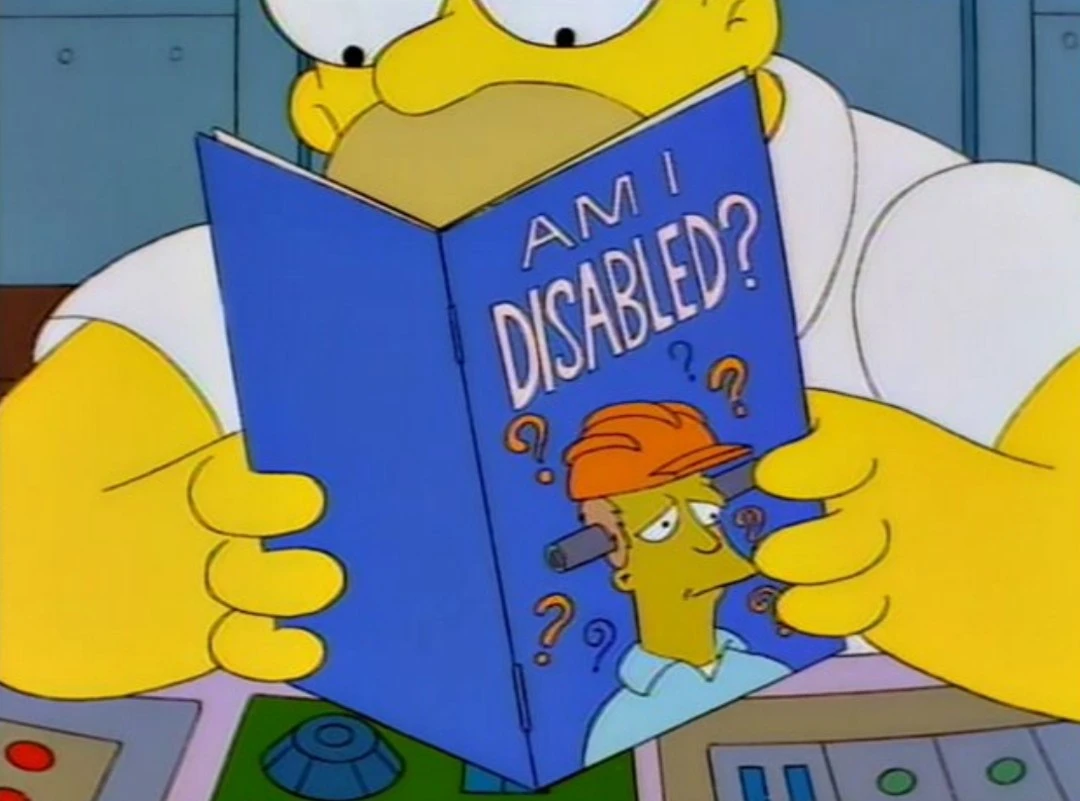

My house is due for some plumbing work and I have decided to go with copper pipe for said work. The thing is I am garbage at soft soldering copper. I never do it so I’m awful at judging the temp and I hate dealing with flux. On the other hand I’m a refrigeration mechanic so brazing copper pipe is my bread and butter. I could practically make a good leak free braze joint with my eyes closed. Also, considering most of the plumbing will be copper to copper connections, I could just use silphos filler rod and not have to worry about flux for most of it. I know brazed joints are not standard for water pipe but I already have the tools, the skill set, and I don’t see any way it could be worse than soft solder. Sure it’s overkill but is there any other reason I shouldn’t just braze my water pipes?

I’ve never ever had an issue sweating copper unless it was really old mating to new. I’ve done plumbing and hvac lines for decades. Brazing seems like more cost and hassle to me.

I recently did some copper soldering and afterwards just wished I had gone with PEX. It’s not like all the connections at both ends aren’t already plastic so you aren’t really gaining anything from using copper and you’re losing a lot.

It still doesn’t beat the long term durability and 100% recyclability of copper though. If I was doing an install in a factory or somewhere where the plumbing would require frequent modification then the fact that pex is easier to work with would probably make me go that route. But in my house where I will be replumbing once and then it will be almost entirely burried in the walls and left alone for decades, I would rather just put the extra work in and do it with copper.

I don’t do it myself, but I have heard everywhere that compression fittings are used for copper pipes nowadays.

When they made some new pipes in my house recently, they used pipes of plastic coated aluminum, very modern, lightweight and they were superfast with handling them.

PEX

Genuinely one of the best developments in construction of the past few decades and people (stupidly) turn their nose up at it because “i want the metal pipes (that are worse in every measurable way)”

Copper won’t be chewed by rodents that unexpectedly gain access to the attic or crawl space, and it doesn’t degrade in sunlight.

I just looked it up, there are videos with rodent-chewed pex, I had no idea it’s possible.

Copper pipes don’t leach microplastics into my drinking water, are 100% recyclable, and are more durable.

Yep there are crimp fittings but they cost more and the seal in those fittings is only rated to last so long. Of course that is a very long time (50 years I think) but I still prefer sweat fit copper that lasts for the life of the pipe.

When the hammer is your only tool, then the rest of the world consists only of nails :)

I would wonder about leaching. Modern lead-free plumbing solder is safe for drinking water, but is silphos considered safe for drinking water?

I’ve found a few references claiming that Sil-Fos brazing rods contain only silver, copper, and phosphorous. They should be fine.

Yep. Thas is all that’s in silphos. For any work that isn’t copper to copper then I would need to use silver brazing wire which is just copper, zinc, tin, and silver.

Since brazing requires higher temps it could damage internal parts to things like shower valves.

The same is actually true of a lot of refrigeration components as well. You just wrap a wet strip of rag around the pipe to act as a heat barier between where you’re brazing and the sensitive component. As long as the rag stays wet (which it will unless you go really slow) then heat won’t significantly propogate past that point. Just doing that can let you braze a joint within 1" of a plastic component as long as you’re careful where you point the torch.

I meant soldering/brazing directly to the shower valve. Which you can do when soldering, I’m no expert on brazing though.

I’m not sure about shower valves in particular but I have devinitely brazed directly to regular nylon core plumbing ball valves before by using the rag trick.in that case you just wrap the valve itself with the wet rag.